Powering the Mitten: Manufacturing, electricity and Michigan’s future

Michigan's manufacturing economy is on the rebound just as its energy future is in flux. How can the Mitten state maintain a strong manufacturing base while transitioning to cleaner energy?

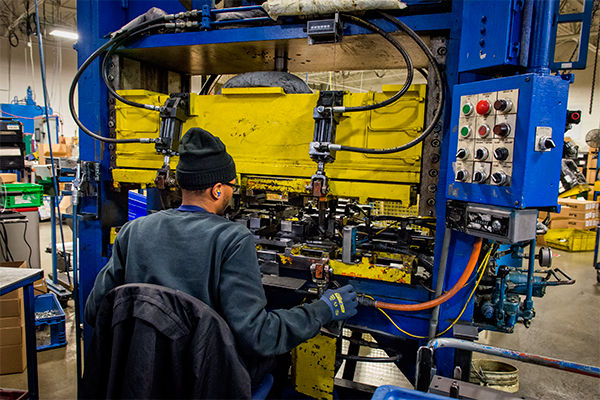

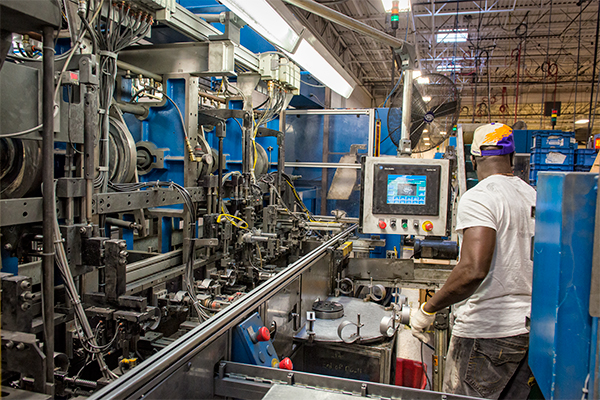

Above: NORMA Group manufactures engineered joining technology for cooling systems, air intake & induction and emission control in Auburn Hills, Michigan.

Even after the auto crisis of 2008, Michigan remains a manufacturing state.

Manufacturing directly employed 556,000 Michiganders—13.5 percent of the non-farm labor force—in 2014, and accounted for 19 percent of Michigan’s GSP, placing us fifth among states in the nation for manufacturing output. And the industry is growing; the number of manufacturing jobs in Michigan has grown by 29 percent since 2009.

We make more than cars and car parts. Michigan is an emerging leader in the manufacture of machinery, food and beverage, biomedical devices, chemical products, and electronics. The state is also taking center stage in advanced manufacturing: in October, Change the Equation, a national nonprofit advocating for STEM literacy, ranked Detroit and Grand Rapids in its top 5 cities for advanced manufacturing jobs in the nation.

Energy-intensive industries like manufacturing depend on reliable, affordable and plentiful power. With Michigan at the crossroads in terms of planning its energy future, the future of our manufacturing economy is also at stake. Work to improve grid resiliency in the face of increased storm-related power outages, a search for alternative power generation options in the short-term to replace the capacity of coal plants expected to retire under new federal carbon regulations, and efforts to improve energy efficiency and chart a way forward for renewable power all have major implications for Michigan’s manufacturing economy.

Differing views on how those implications should be addressed were expressed at a recent town hall meeting in Detroit, sponsored by the Atlantic and underwritten by the American Petroleum Institute, in which academics, environmentalists and manufacturing industry reps faced off in a discussion on the best way to move Michigan’s manufacturing and energy economies forward.

A subsequent pair of op-eds in the Detroit News summarizes those differences. In an opinion titled “Michigan manufacturers still need fossil fuels,” Mike Johnston, vice president of government affairs at the Michigan Manufacturers Association writes:

“While some celebrate the regulatory vice grip on the primary source of electricity and the increased costs imposed by the regulations, manufacturers are concerned about our ability to sell our Michigan-made products at a competitive price. Shutting these plants abandons the billions of dollars ratepayers have paid to build these plants over the years, and forces the construction of new generation.”

In an opposing opinion titled “Renewable energy crucial to Michigan,” Michigan Environmental Council president Chris Kolb writes:

“For a strong manufacturing sector, we need an energy strategy that keeps costs down, minimizes the risk of price spikes, promotes economic development and preserves excellent reliability. Making energy efficiency and renewable power the foundation of our energy policy will achieve those goals while also protecting public health and the environment — themselves core components of a thriving economy.”

One things is clear: both the energy sector and the manufacturing sector in Michigan are in for some big changes in the coming years, and their fortunes are closely aligned.

“With manufacturing customers, their equipment is sensitive and highly technical,” says John Boladian, Director of Customer Billing at DTE Energy. “They all want reliability, just like a residential customers, but they need reliable power from a quality standpoint. Any type of outage severely impacts their business, because their inventories are maintained at such a very low level.”

Manufacturing plants are a high priority for restoration during outages, says Boladian, along with public safety services and hospitals. DTE also works directly with manufacturing customers to identify ways to maintain reliable power supply while also reducing costs, such as building increased redundancies and dedicated substations.

“There are costs associated with that because those substations are dedicated just for that business,” says Boladian. “But sometimes their load really does require it; they need that type of service.”

Boladian also works closely with manufacturing firms to recommend energy efficiency improvements as a way to reduce demand on the grid while also saving money and increasing profitability.

“We really work closely with them on energy efficiency,” says Boladian. “We help to identify priorities for specific types of technology, like LED lighting, that can drive more efficiency.”

Dan Radomski is Vice President for Industry and Venture Development at NextEnergy, a Detroit-based nonprofit clean technology accelerator. Radomski would like to see expanded financing options to help manufacturers implement energy efficiency.

“There are plenty of small and medium sized manufacturing firms across the state that would love to do an energy efficiency upgrade,” says Radomski. “The ROI for things like LED lighting and even solar panels has gone way down. But businesses still can’t spare the upfront money for the investment; they need that borrowing capacity to do things like upgrade equipment for their businesses.”

Radomski would like to see adoption or expansion of innovative methods to help with that upfront investment. Such options include on-bill financing, in which utilities bear the upfront cost and customers pay over time on their utility bill, PACE financing, in which the cost of upgrade is rolled into the tax assessment, and low-interest guaranteed loan programs like Michigan Saves.

“I think the first thing the state should do is have some creative financing programs for energy efficiency,” says Radomski. “That’s the lowest hanging fruit. Not only does it make Michigan’s businesses more energy efficient, it improves their profit margins. And, what often gets overlooked, is that it prevents utilities from having to invest in new power generation. That’s the whole goal.”

Currently, Michigan’s energy law, Public Act 295 of 2008, requires utilities to reduce energy use by one percent of sales per year. That law sunsets in 2015, and Radomski would like to see the standard increased.

“Let’s do it at 2 or 5 percent, and eliminate the need for new power generation,” he says. “We support renewables, but it’s better if we don’t even have to put in new wind turbines, or any new power generation.”

Boladian also points out that Michigan’s engineering and manufacturing talent uniquely positions us to lead the way in designing and manufacturing clean energy technologies such as energy storage and wind turbines.

“Michigan is one of the best places in the world for designing and manufacturing products,” he says. “We’ve worked very closely with automation firms and custom equipment manufacturers to automate manufacture of wind turbines and solar panels, and introducing new materials to allow those products to be more robust and cost less to make. We’ve helped hundreds of companies get into the wind and solar supply chain over the past several years. As markets mature and supply chains are globalized, it may change where they are manufactured, but they will always have an opportunity to be designed here.”

Current incentives in Michigan’s energy law encourage sourcing from Michigan customers, but Radomski would like to see those incentives strengthened.

“As we make investment in power generation facilities, whether natural gas, solar, or wind turbines, how do we make sure those investments are taking into consideration the economic development potential for our Michigan manufacturing base?”